My aerox has a city 16

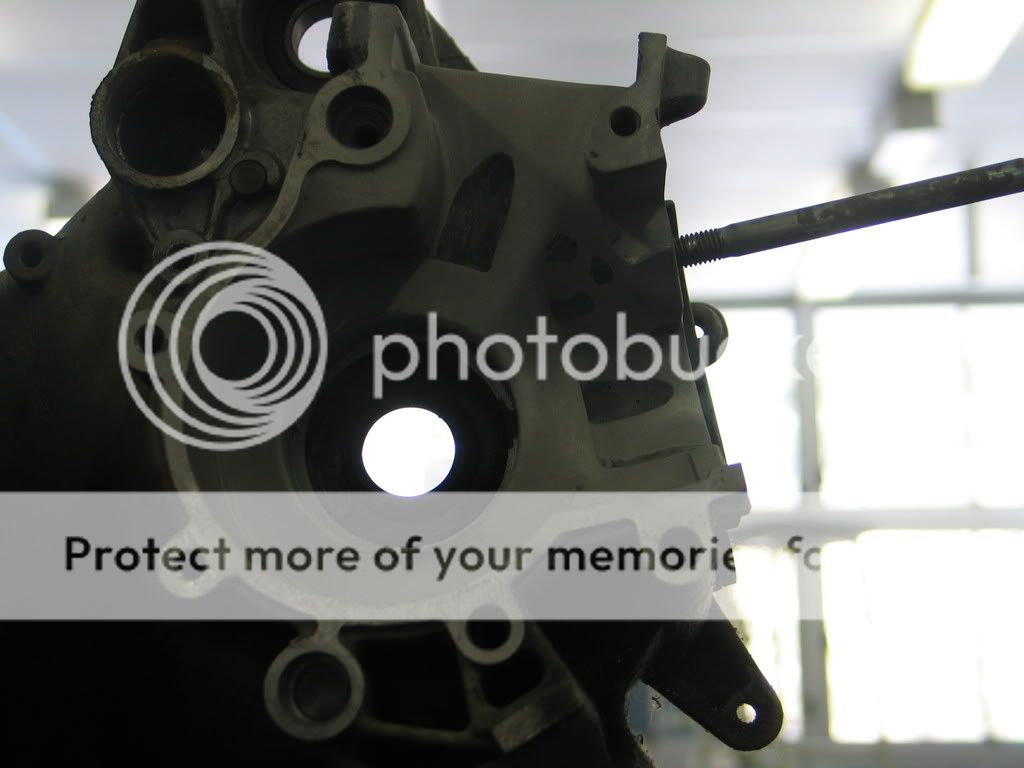

a ported motoforce cylinder

130 transfers

194 exhaust

v-force reeds

21mm delorto

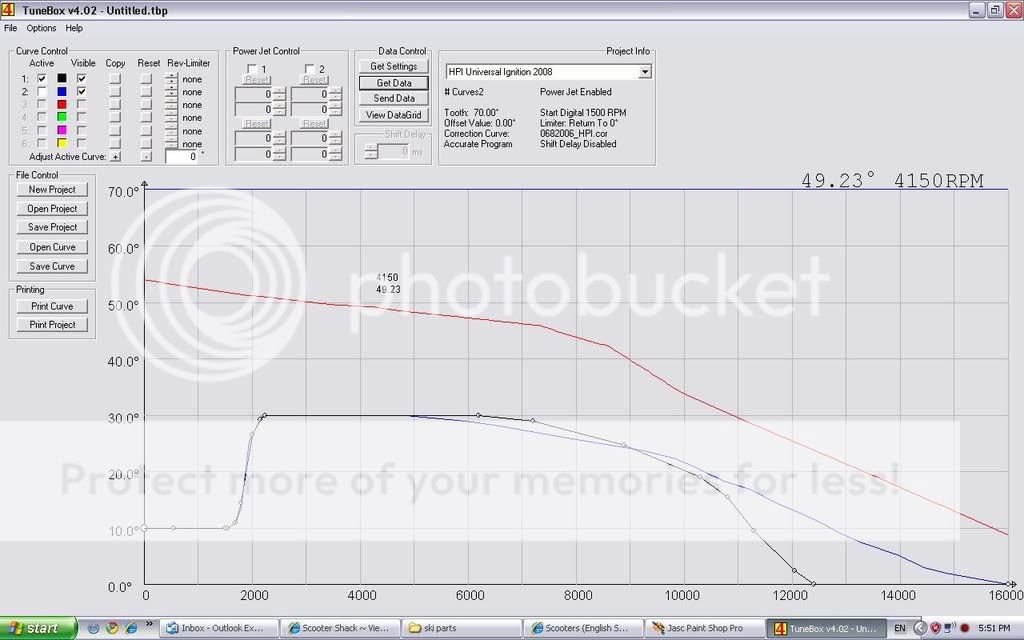

programable ignition ( my own) www.waxracing.com

i am waiting for my delta clutch springs to turn up so i am running a stock clutch with lightened shoes and heavy springs

when the power hits the engine revs and then a split 2nd later it takes off

Its still quick but it seems to me that once it gets going it seems to acelerate faster

could this be a slipping belt or a slipping clutch

it comes on hard at about 9500-10000

and revs to about 11500

Any help would be greatly appreciated

a ported motoforce cylinder

130 transfers

194 exhaust

v-force reeds

21mm delorto

programable ignition ( my own) www.waxracing.com

i am waiting for my delta clutch springs to turn up so i am running a stock clutch with lightened shoes and heavy springs

when the power hits the engine revs and then a split 2nd later it takes off

Its still quick but it seems to me that once it gets going it seems to acelerate faster

could this be a slipping belt or a slipping clutch

it comes on hard at about 9500-10000

and revs to about 11500

Any help would be greatly appreciated

Last edited: