You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blown Fan

- Thread starter Mexicano

- Start date

Astrolopitec

Well-Known Member

Mexicano said:Yes Juan, it is.

Got it from Dave's as yours....hecharged me extra $75.00 Usd. for porting the cylinder and looks pretty well done.

He's got tons of first hand experience with strokers.

If your modified C20 pipe turns out to be a good match. You are going to have trouble keeping your front wheel down.

BTW. You might have to lower the squirts down 3-4mm to fit in the crankcase.

Last edited:

brookespeed

Well-Known Member

what is a squirt?

Mexicano

Mexicano

Astrolopitec said:He's got tons of first hand experience with strokers.

If your modified C20 pipe turns out to be a good match. You are going to have trouble keeping your front wheel down.

BTW. You might have to lower the squirts down 3-4mm to fit in the crankcase.

Do You mean piston skirt?...... the lower part of piston?

tiba_karotsu

OVERREV TUNING

mhr

Astrolopitec

Well-Known Member

Mexicano said:Do You mean piston skirt?...... the lower part of piston?

Sorry for my spelling. Yes I meant skirt.

there is an arrow on that piston crown and its drawn in the wrong way !!Mexicano said:The crankshaft, the cylinder & piston and the head arrived:

brookespeed

Well-Known Member

Astrolopitec said:Sorry for my spelling. Yes I meant skirt.

The piston skirt should be ok, it's the spigot of the cylinder that may be too long. But his cases are not conversions like ours. His came stock with the longer stroke and bore. Rather than cut the spigot I ground out some room in the cases. Had to fix a small mistake with JB weld but it's held up fine so far. I think next time I'll cut the spigot a bit though as you suggest.

Astrolopitec

Well-Known Member

Yes I meant the cylinder skirts. Not the piston skirts.

I did not know that the cylinder skirts were called spigots .

Brookespeed.

I forgot.... What motor are you running ?

Thanks.

I did not know that the cylinder skirts were called spigots .

Brookespeed.

I forgot.... What motor are you running ?

Thanks.

Mexicano

Mexicano

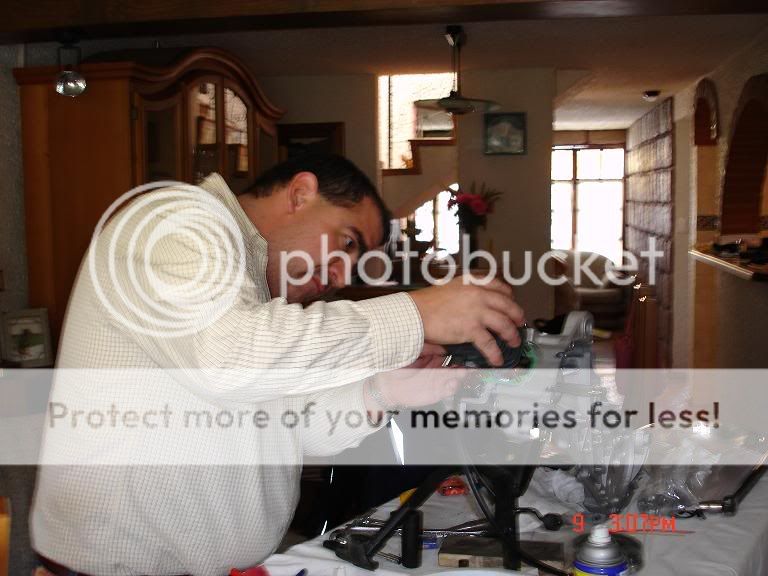

brookespeed is right, Juan.....my cases are bigger than yours...my guess is I wouldn't need to cut the cylinder...maybe I will need to machine the cases just a little to accept the larger cylinder and cranckshaft stroke....now I'm waiting for the new cases....2 more weeks!

Last edited:

brookespeed

Well-Known Member

I think the 47mm stroke cranks may need some grinding on the cases even for the motors that normally run a 42mm stroke. I was told the 45mm stroke cranks do not require modification.

I built a zuma stroker with a 42mm crank and a 54 bore. It's been run but it didn't run well so I have been working on it when I can. I just welded up a ghetto pipe and plan on firing it up to check the timeing sometime in the next week. we'll see.

I built a zuma stroker with a 42mm crank and a 54 bore. It's been run but it didn't run well so I have been working on it when I can. I just welded up a ghetto pipe and plan on firing it up to check the timeing sometime in the next week. we'll see.

Mexicano

Mexicano

J J Tuning said:very nice, BUT the starter gear is going to demolisch ur crank again for sure...

Those are the things u can bether leave @ home if u want to make rpm's ..

I hope no...... anyways I will evaluate if use it or no....will tell you later.

Similar threads

- Replies

- 20

- Views

- 4K